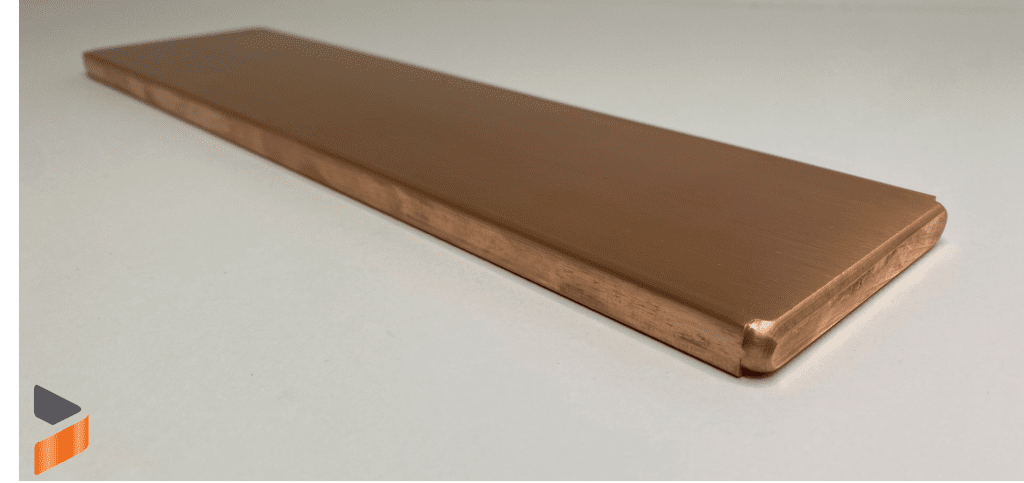

The Vaski Shape Series plays a vital role in the electrical and manufacturing sectors by delivering consistent, high-quality finishes to copper busbars. Proper finishing is essential for both performance and safety, particularly when working with flat and round copper bars. This advanced solution enables manufacturers to achieve smooth, uniform edges with precision, reducing manual intervention and improving efficiency.

At ILF Products, we’ve witnessed how the Vaski Shape system enhances handling safety, improves visual quality and contributes to a longer service life, especially in demanding, high-performance environments.

What Is a Busbar and Why Does Its Shape Matter?

A busbar is a flat strip or bar made of a metal that conducts electricity, like copper or aluminium. It’s used in electrical distribution boards and industrial control tools to carry electricity. An important benefit of a busbar is that it can carry large currents and send power to many outputs easily.

Busbars have usually been flat, solid, or tube-shaped. But engineers are looking into optimised shapes more and more to deal with problems like overheating, limited installation room, and loss of electricity. This is where the Vaski form comes in.

What Is the Vaski Shape?

Vaski is a distinctively shaped busbar profile that looks like a wider “V” or a bent fin. The cross-sectional shape, as opposed to a flat one, increases the surface area, which helps dissipate heat much more effectively. Despite the seemingly specialised nature of the term, “Vaski” actually stands for a solution based on real-world engineering problems that experts in the UK face regularly. These problems manifest most noticeably when building modular switchgear systems or tiny control panels.

There is more to this form than meets the eye. Its structural, electrical, and thermal benefits aid systems in meeting ever-tightening regulations while cutting down on unnecessary energy consumption.

The Benefits of the Vaski Shape in Real-World Applications

- Enhanced Thermal Management:

Heat generation is a major power distribution design challenge. Current flowing through the busbar generates heat due to resistance. Compact enclosures are more likely to overheat.

The Vaski form increases air-exposed surface area. This improves heat release without substantial cooling. This thermal advantage can minimise fan-assisted ventilation in high-demand UK business and manufacturing buildings, boosting energy efficiency.

- Optimised Electrical Distribution in Compact Spaces:

Modular and small electrical systems are becoming more common. Flat busbars can be space-consuming or design-restrictive. The Vaski shape can fit into tighter spaces while transporting a lot of current.

This simplifies consumer unit and switchgear system integration for contractors and installers without affecting performance. It’s useful for upgrading older systems with limited space.

- Improved Current Density Distribution:

Electrical current rarely flows uniformly through a conductor. The skin effect causes current to concentrate at the surface of a flat busbar. Vaski form distributes current evenly over its surface, disrupting this propensity.

Hotspots are reduced, the busbar lasts longer, and safety is improved, which is vital in residential and commercial applications.

- Mechanical Rigidity and Durability:

The mechanical qualities of the busbar are just as important as its electrical ones in systems that are likely to shake or expand when the temperature rises. The Vaski form is naturally strong and rigid because of how it is built. This helps keep it from bending when it’s under mechanical stress, so it can be used in harsher places like train transport, aerospace, and heavy industrial installations.

Applications Across UK Industry

Many UK infrastructure projects, electrical contractors, and design engineers are using modern busbar technology to achieve energy efficiency and BS EN criteria. Integrating better-performing, longer-lasting busbars into substations, renewable energy systems, and new housing complexes is a game-changer.

In healthcare, education, transit, and commercial development, Vaski control panels, busbar trunking systems, and switchboards are becoming more popular.

Where precision electrical systems power functionality behind the scenes at ILF Products, busbar system design and arrangement can affect performance, compliance, and long-term maintenance. Smart components like Vaski-shaped busbars help build sustainably and efficiently.

How to Determine if the Vaski Shape is Right for Your Project

Not all projects need this advanced profile. The Vaski form is appropriate for systems with current ratings over 800 amps, space limits, or limited ventilation. It also helps in high-humidity or thermally changing circumstances.

An electrical design expert or supplier who understands the Vaski profile can help decide if it’s suited for property developments and installations where long-term reliability and efficiency matter.

These technologies assist ILF Products, which relies on integrated control systems and constant electrical performance, decreases failure risk and consumes cleaner, greener electricity.

Shaping the Future

Vaski shapes aren’t merely innovative; they solve problems in electrical engineering that people face. Increasingly popular in the UK’s power industry, it offers several advantages, including better thermal performance, spatial economy, and current handling.

Anybody working on infrastructure, home installs, or industrial upgrades would do well to familiarise themselves with how design advances, such as the Vaski form, might improve their system. Our electrical networks are subject to ever-changing demands, which means the components we use to maintain them efficiently must also adapt.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.