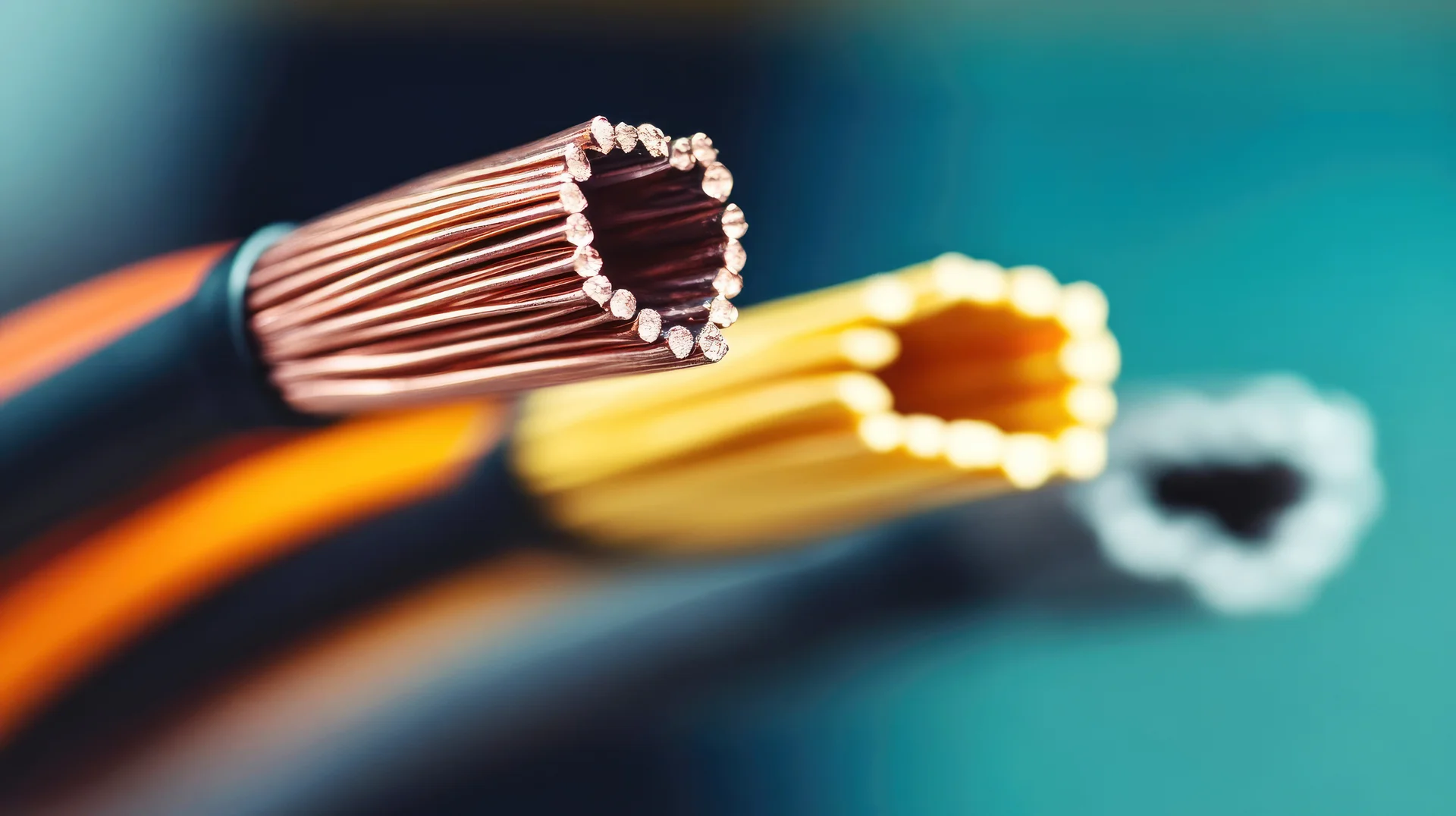

Engineers and specifiers often meet the term cuponal when they need the conductivity of copper with the weight and cost benefits of aluminium. Cuponal is a well-known copper-clad aluminium product where a copper layer is metallurgically bonded to an aluminium core. Bimetal cladding more broadly describes any product where two different metals are permanently joined to create one composite section. This guide sets out what the materials are, how the bond forms, and how to specify and install them with confidence on modern UK projects.

How Cuponal Works?

Cuponal combines a copper sheath and aluminium core continuously via pressure and diffusion. Interface is not glue. This metallurgical junction resists peel and delamination under normal service loads. In many applications, current accumulates near the outer surface, so the copper layer conducts electricity while the core decreases in weight. When specified appropriately, that balance can save material and simplify installation without losing performance.

Early discussions with a trusted stockist like ILF Products assist project teams in matching section sizes and shapes to site duty cycle and fault ratings. This is helpful when replacing a pure copper busbar in tight switch rooms or on rooftops.

The Science Behind Bimetal Cladding

Managing Dissimilar Metal Interfaces

Every bimetallic solution must control galvanic effects where dissimilar metals meet. The manufacturing route for Cuponal forms a tight bond with minimal voiding, which limits electrolytes from entering the interface. In practice, correct jointing and the use of approved contact compounds further reduce corrosion risk. Where the composite meets other materials, installers should use compatible fasteners and joint designs that keep moisture away from the interface.

Thermal and Electrical Performance

Copper has lower resistance and higher thermal conductivity than aluminium. Copper on the composite surface reduces termination contact resistance and improves joint heat dissipation. Aluminium cores improve strength-to-weight ratios. Designers must compare current ratings, temperature rise, and voltage drop to installation method, environmental conditions, and enclosure details. Modelling expansion and contraction for dynamic duties ensures clamps and supports maintain pressure.

Manufacture, Quality Control and Standards

Bimetal cladding processes differ. Copper and aluminium are bonded under controlled pressure and temperature for Cuponal. Inspections include bond integrity, layer thickness, straightness, and surface finish. Designers follow British and worldwide conductor, busbar, and earthing standards, while sector requirements vary. Safety-related applications benefit from continuous heat batch and test certificate traceability.

Typical Applications and Sector Use

Busbar systems, earthing, power distribution, rising mains, transformer linkages, and connectors employ cuponal. In heat exchangers, cookware, architectural panels, and marine fixtures, bimetal cladding has important features beyond power. Onboard electrical systems in transit benefit from composite metals’ weight reduction and energy efficiency. Easy-to-lift and align conductors help fit out high-current, space-constrained data centre assemblies.

Many ILF Products teams assist contractors in replacing outdated plant in existing structures. If the installation design accounts for jointing and inspection, composite conductors can simplify logistics in tight access routes and limited crane time.

Advantages, Limitations and Risks

Benefits:

- Lower mass per unit length compared with pure copper for the same current rating.

- Reduced material cost exposure where copper pricing is volatile.

- Low contact resistance thanks to the copper layer at the surface.

- Good mechanical strength and stiffness from the aluminium core.

Limitations:

- Jointing requires approved techniques and attention to surface preparation.

- Incorrect termination hardware can introduce galvanic couples and local heating.

- Minimum bend radii and support spacing must be respected to protect the bond.

- Repair of damaged outer layers is not straightforward and may require replacement.

Common Failure Modes and Prevention:

- Overheating at joints is usually due to insufficient contact pressure or contamination. Prevent with careful surface preparation, calibrated torque and post-installation thermal checks.

- Crevice corrosion where moisture is trapped at dissimilar metal interfaces. Prevent with correct sealing, compatible compounds and enclosure design that manages condensation.

- Mechanical fatigue from vibration or thermal cycling. Prevent with proper supports, expansion gaps and flexible links where necessary.

Design and Installation Best Practice

Early design choices pay off. Check route, enclosure type, ambient temperature, and fault levels before choosing section sizes. Use authorised connectors for couplings that maintain pressure without cold flow. Before assembly, remove oxides from both metals. Use the jointing compound sparingly and without grit. Set the torque to the manufacturing range and record quality values.

Supports should prevent sag without overclamping. Allow thermal movement using sliding supports or expansion joints for lengthy lines. Externally, prevent standing water and provide drainage. Consider ingress-protected enclosures or surface treatments in corrosive environments.

Inspection, Testing and Maintenance

Visual joint inspection, torque verification, and thermal imaging under load should be part of commissioning. Additional thermal surveys can show bedding-in effects after the first service period. Check for discolouration, insulation damage, loosening, corrosion, and water penetration periodically. Isolate anomalies, disassemble, clean contact faces, and replace hardware.

Keep records for reliability. Save drawings, calculation notes, test certificates, and maintenance logs so future teams may understand the design intent and installation state.

Future Trends for Composite Metal Solutions

Electricity, microgrids, and higher-density plants will tighten space, weight, and efficiency. These requirements suit composite conductors like Cuponal. Improved bonding, intelligent joint hardware that monitors pressure and temperature, and digital twins that replicate heat rise and lifespan performance are expected. Design will focus on how readily assemblies can be recycled and how waste is reduced during manufacturing.

Key Takeaways

Cuponal places copper where it’s most electrically beneficial and aluminium where it minimises mass and cost. Sound interfaces, well-designed joints, and disciplined installation make bimetal cladding work. These composite solutions assist efficient, low-carbon systems in power and infrastructure projects with proper specification, commissioning, and maintenance.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.