Aluminium extrusion plays a vital role in a wide range of industries across the UK, including construction, automotive manufacturing, engineering and aerospace. Whether you are new to the process or simply want a deeper understanding of how it works, this guide is designed to provide clear, practical insights based on real-world applications.

With this guide, you’ll understand what aluminium extrusion is, how the process works, its many uses, and how to choose the right profiles for your specific project. ILF Products, one of the recognised names in the sector, supports this process through its experience in the aluminium supply chain.

What is Aluminium Extrusion and How Does It Work?

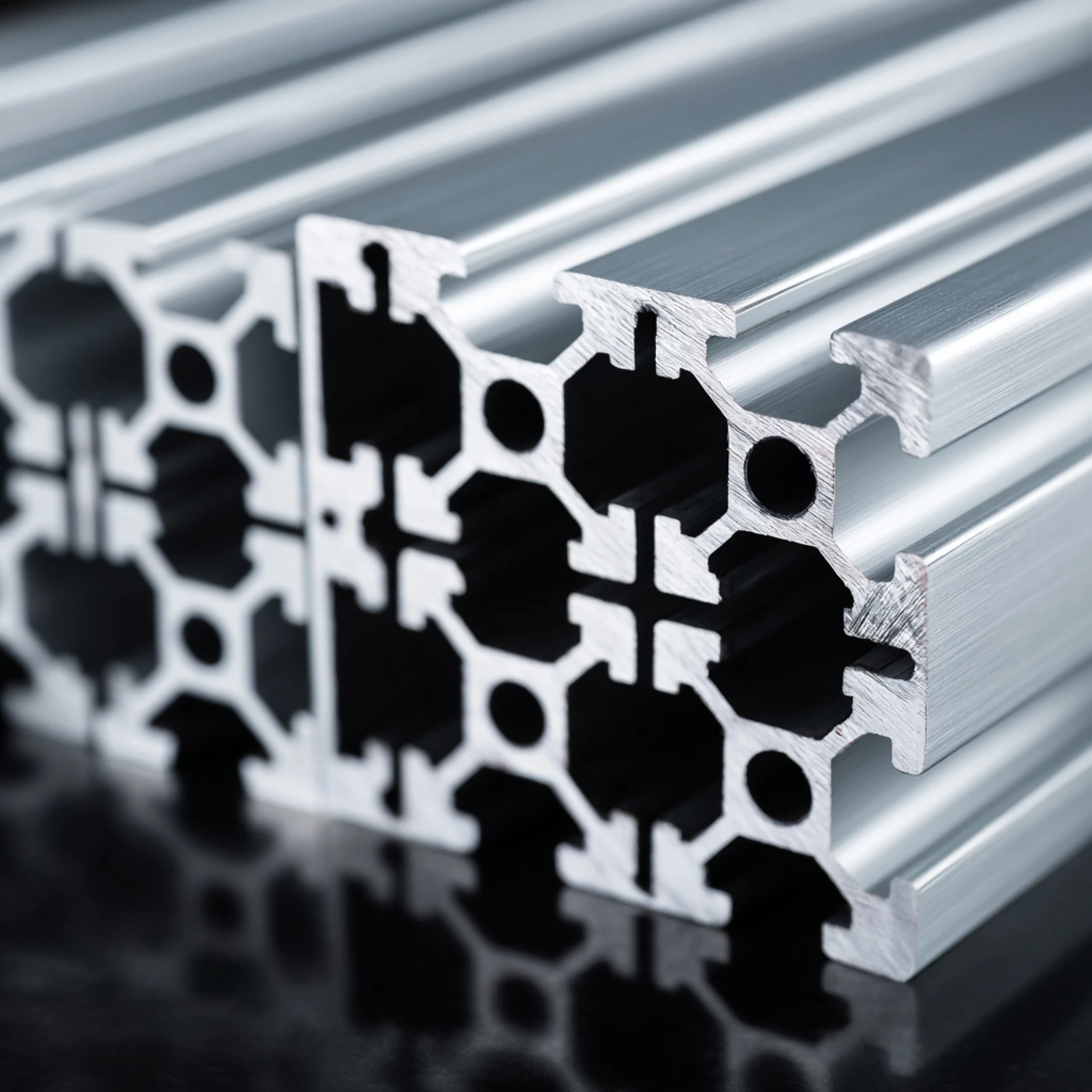

Aluminium extrusion is a forming process where aluminium billets are pressed through a designed die to create profiles with uniform cross-sections. This approach enables the fabrication of complicated shapes with excellent strength and minimal waste. Manufacturers commonly use aluminium because it is both lightweight and corrosion-resistant, making it excellent for applications that need endurance and performance.

The Key Advantages of Aluminium Extrusion:

- Versatility in Design: Custom shapes are easily achievable.

- Lightweight and Strong: Perfect for structural applications.

- Efficient Production: Continuous lengths reduce machining and welding.

- Sustainable: Aluminium is highly recyclable with minimal quality loss.

In the UK, this process supports a variety of sectors where precision, structural strength, and energy efficiency are critical.

The Aluminium Extrusion Process Step-by-Step

To fully grasp how this process works, it’s important to break it down into stages:

- Billet Preparation: Raw aluminium logs are cut into billets and heated to around 450 to 500°C. This makes the metal malleable without affecting its structural properties.

- Extrusion: The aluminium billet is loaded into a container and pushed through a steel die using a powerful hydraulic press. As the aluminium moves through the die, it takes on the die’s shape.

- Quenching: The extruded profile is cooled quickly using air or water to retain its mechanical properties.

- Cutting and Stretching: The profile is cut to the desired length. A stretching process ensures the final product is straight and stress-free.

- Ageing or Heat Treatment: Manufacturers heat-treat some profiles to enhance their strength, depending on the alloy and intended use.

- Finishing: Manufacturers apply surface treatments such as anodising or powder coating to improve aesthetics and resistance to corrosion.

Typical Applications of Aluminium Extrusion in the UK

Domestic and commercial sectors use aluminium extrusions extensively. Here are just a few of their many uses.

- Architecture and Building: Window frames, curtain walls, door systems, and roofing structures benefit from lightweight and corrosion-resistant extruded sections.

- Transport and Automotive: In electric vehicles and public transport systems, weight reduction is essential. Extruded aluminium supports frames, battery trays, and internal fittings.

- Industrial Equipment: Conveyor systems, automation rails, and structural frames take advantage of aluminium’s formability and strength.

- Consumer Products: Items like ladders, tools, lighting frames, and electronics enclosures often rely on extruded parts for their cost-effectiveness and versatility.

Choosing the Right Aluminium Extrusion Profile

When selecting a profile, consider the following:

- Application Load and Environment: Will the extrusion be under mechanical stress or exposed to moisture and chemicals?

- Alloy Selection: Different aluminium alloys have different powers, levels of corrosion resistance, and levels of ease of machining. For instance, 6063 is great for architecture because it has a smooth surface and doesn’t rust.

- Tolerance and Precision Needs: High-precision industries, such as aerospace and medical device manufacturing, may require tighter tolerances.

- Surface Finish Requirements: Aesthetic and protective coatings, such as anodising, are often necessary depending on the final use.

ILF Products works with a range of clients to ensure the correct profile and finish are specified for each project, ensuring long-term performance and compliance.

Common Alloys Used in Aluminium Extrusion

In the UK, a few standard alloys dominate the extrusion market due to their availability and performance:

- 6063: Best for architectural applications. Easy to anodise and shape.

- 6082: Offers high strength and good corrosion resistance, widely used in transport and structural applications.

- 6061: Popular for a balance of strength and corrosion resistance. Used in marine and aerospace industries.

Each alloy type offers different combinations of strength, weight, corrosion resistance, and finishing suitability. Understanding the use case helps determine the best material for the project.

Sustainability and Aluminium Extrusion

One of the most eco-friendly metals used in production today is aluminium. To cut down on carbon emissions without sacrificing quality, the UK industry is putting more effort into using recycled metal. Extrusion produces very little waste, and manufacturers can often return leftover material to the supply chain.

We buy and process materials in a way that is environmentally friendly, which is in line with larger environmental goals in the manufacturing and building industries.

What to Remember

Businesses in the UK can make parts for almost any industry quickly, easily, and environmentally friendly way through aluminium extrusion. Its benefits are hard to ignore, from making car frames lighter to adding modern touches to buildings.

If you know about the process, the benefits, and the different types of materials, you can plan your projects better and work with dependable sources like ILF Products to reach your technical and business goals.

This flexible method will continue to help the UK manufacturing sector be more innovative, whether you’re just thinking about design ideas or are ready to make a lot of them.

Contact one of the aluminium specialists here at ILF Products, who can advise on the best way to move your project forward. In the first instance, you should email info@ilfproducts.co.uk

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.