Copper profile has been a staple material across various sectors in the UK, prized for its durability, conductivity, and corrosion resistance. Whether you’re working on a construction project, installing electrical systems, or designing interior fixtures, choosing the right custom copper profile is essential for achieving long-term functionality and visual appeal. This guide will help you understand the different copper profiles available and how to match the right one to your specific application.

Understanding Copper Profiles and Their Uses

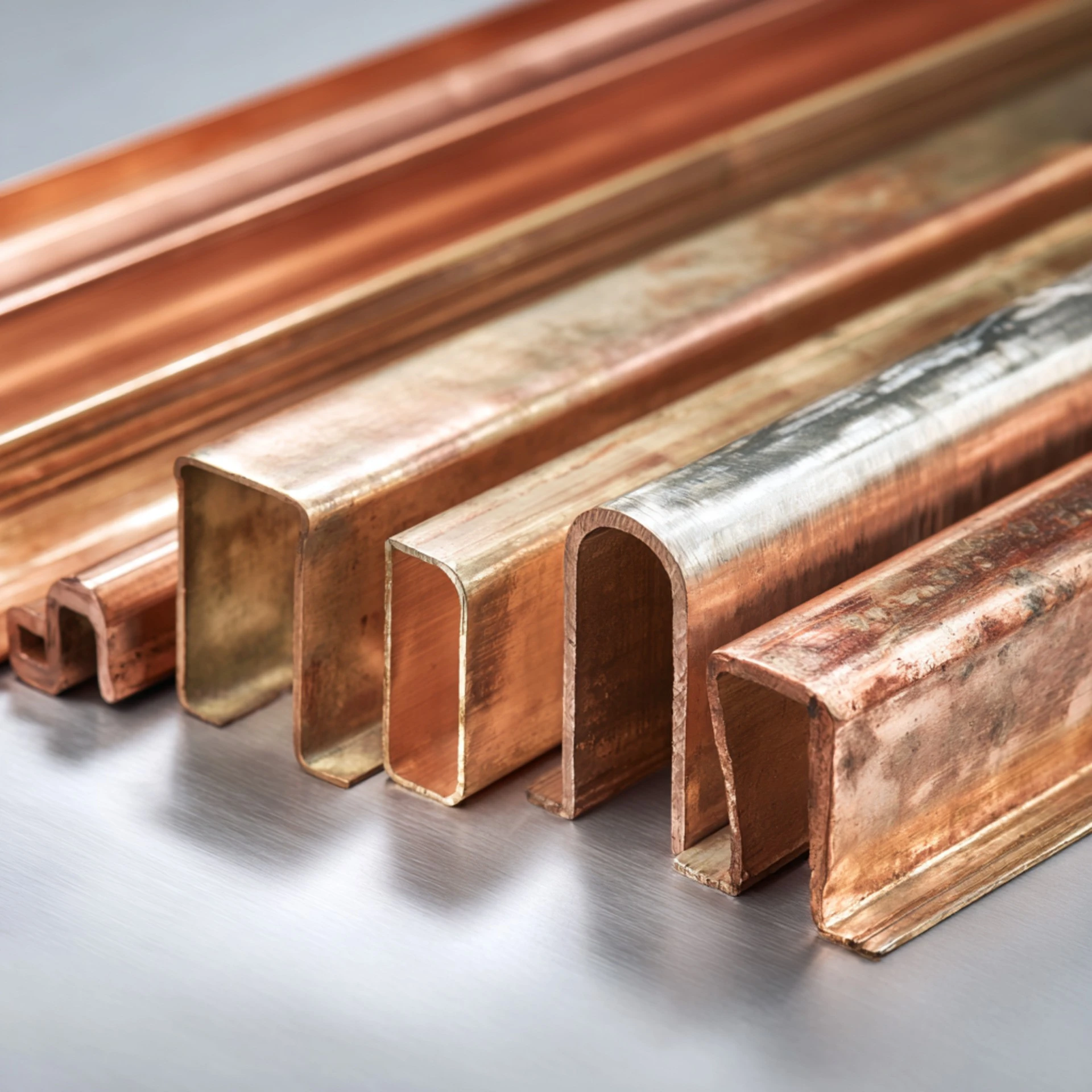

Copper profiles are semi-finished materials tailored for performance. Custom extrusions, flat bars, rods, tubes, and channels are examples. The location and use of each variety determine its benefits.

Architecture uses flat and U-shaped profiles for cladding, flashings, and decorative embellishments. They age naturally, giving structures a timeless look. Copper tubing is used for plumbing and heating systems due to its thermal transmission and ease of installation.

Electrical engineering uses copper extrusion extensively. Switchgear, transformers, and control panels need busbars and flat conductors to properly distribute current. With copper’s high conductivity, even modest cross-sectional area changes can affect performance, making profile selection critical.

Key Considerations When Selecting a Copper Profile

There are a lot of technical and useful things to think about when choosing the right copper profile. This is what you should remember:

1. Application Type

The copper profile’s size and form depend entirely on its intended use. Architects focus on appearance and how easily the material shapes. In contrast, industrial projects prioritise electrical or thermal performance. Once you understand your project’s exact needs, you can narrow down your options with confidence.

2. Mechanical Properties

Copper comes in different types and tempers, which change how strong, hard, and flexible it is. For example, high-tensile copper profiles are great for parts that are stressed or that have to handle big loads. Softer tempers, on the other hand, are easier to shape and bend, which makes them good for cold working or fine details.

3. Thermal and Electrical Conductivity

If your project includes moving heat or power, conductivity should be your first choice. Most of the time, electrolytic tough pitch (ETP) and oxygen-free copper (OFC) copper are best for these uses. These grades are used to make profiles that have low resistance and great efficiency.

4. Corrosion Resistance

Copper is ideal for outdoor applications because it resists air corrosion. However, in harsh locations like coastal or industrial zones, profile longevity must be considered. Such situations may require protective coatings or alloys.

5. Dimensional Accuracy and Tolerances

Electrical engineering and high-tech manufacturing require precision. Mismatched sizes or tolerances can cause installation, safety, and efficiency difficulties. With suppliers like ILF Products, you can request specific tolerances or profiles for your project.

6. Sustainability and Recyclability

Copper is one of the most recyclable elements, and sustainability is becoming a procurement factor. Green goals can be met without sacrificing quality with recycled copper. Always check if the profile you’re buying has recycled components, especially for huge developments or government-backed projects.

Common Copper Profile Types Explained

Projects vary, but you’ll often see certain copper profiles used in specific ways. Here’s a brief breakdown of the most common types and their typical applications:

- Flat Bar: Typically used for busbars in electrical systems, decorative cladding and trims.

- Angle Profile: Ideal for frames, reinforcements and corner protection.

- Channel: Suited for drainage channels, structural support and cable containment.

- Round Bar: Often used in engineering components, supports and fastenings.

- Tube or Pipe: Essential in plumbing, HVAC systems and gas supply lines.

By matching the profile shape to the application, you reduce waste and ensure the material performs well in situ.

Why Quality and Source Matter

Beyond shape and size, profile copper consistency and purity are crucial. Low-quality materials can break down or need replacement early. Therefore, you must use experienced manufacturers and suppliers.

A trusted UK provider, ILF Products, offers a comprehensive choice of copper profiles supported by engineering expertise and UK standards. Technical guidance, reliable delivery, and goods that meet your needs are available from industry-experienced suppliers.

Selecting the Best Fit

Selecting the proper copper profile is a strategic decision that affects project efficiency, cost, and durability. Understanding your performance, environmental, and compliance criteria is crucial whether you’re handling a modest refurbishment or a large infrastructure project.

Consider these aspects early on and work with trustworthy suppliers like ILF Products to make a smart option that helps your project succeed. Buying the proper copper profile today can help you prevent unnecessary changes, decrease operational concerns, and offer a long-lasting finish.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.