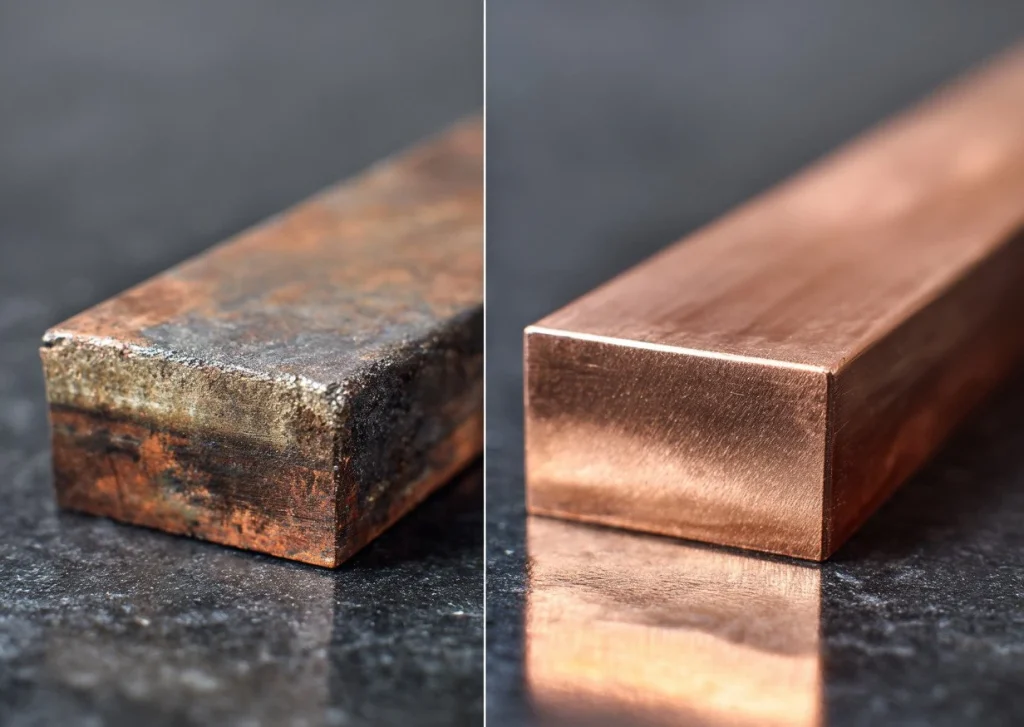

When people think about busbar reliability, they usually focus on the obvious things: current rating, heat rise, fault level, and the joint design. But in day-to-day manufacturing and maintenance, some of the biggest headaches start with something far simpler.

At ILF, we see it often. A busbar can be perfectly sized and beautifully laid out, but then a small burr or a rough edge leads to problems during assembly, insulation damage, unexpected hot spots, or annoying rework on site.

This post explains what deburring and edge finishing mean for copper and aluminium busbars, why it matters, and how to specify it clearly without turning your drawing into a novel.

What is a burr?

A burr is a small ridge of material left behind after cutting, punching, drilling, or machining. It often appears:

- along the edge of a flat bar after sawing or shearing.

- around a hole after drilling or punching.

- on the exit side of a cut.

- where a bend or formed feature has been trimmed.

Copper and aluminium both produce burrs, but they do so in slightly different ways. Aluminium burrs can feel softer, but can still be sharp and can still interfere with insulation or joint faces. Copper burrs can be tougher and more stubborn, and they can create very sharp edges.

What does “deburring” mean?

Deburring is simply removing those burrs so the part is safer, cleaner, and fits as intended. It is not the same as polishing a part for looks. It is a practical quality step that improves assembly and reliability.

What does “edge finishing” mean?

Edge finishing extends the process. It means shaping and smoothing the edge so it has a controlled finish.

Typical edge finishes for busbars include:

- a light edge break (taking the sharp corner off).

- a small chamfer.

- a small radius on corners and edges.

- smoothing around holes and slots.

The right choice depends on how the busbar is being installed, insulated, plated, and handled.

Why Edges Matter More Than You Might Think

1) Better electrical joints and fewer hot spots

Busbar joints rely on clean contact faces and consistent pressure to ensure reliable operation. Burrs and raised material around holes or near contact areas can:

- Stop two surfaces from seating properly.

- Reduce real contact area.

- Concentrate the current in smaller patches.

- Increase local heating.

That is the sort of thing that can look fine at installation, then show up later as a warm joint, discolouration, or a maintenance issue.

2) Reduced risk of insulation damage

If a busbar is sleeved, coated, or installed close to insulation materials, sharp edges can:

- Cut the heat shrink during installation.

- Nick sleeving as the bar is slid into position.

- Wear through insulation over time if there is vibration or thermal movement.

A small radius or controlled edge break can make insulation work far more dependably.

3) Faster assembly and fewer “fiddly” issues

Deburred parts:

- Fit together more easily.

- Align better in stacks.

- Reduce snags when feeding through enclosures.

- Make handling safer for installers and workshop teams.

It is one of those steps that quietly saves time throughout the entire build.

4) Improved plating and coating results

If you are plating copper busbars or applying protective coatings, edge quality matters. Rough edges and burrs can create:

- Uneven coating build.

- Thin spots on sharp corners.

- Poorer cosmetic finish.

- Areas where contamination can cling.

A consistent edge finish supports a more consistent final product.

5) Safety and professionalism

It is worth saying plainly. Sharp copper or aluminium edges can cut hands and gloves. Deburring is a basic expectation in professional manufacturing, especially in electrical assemblies.

Where Burrs Usually Cause Trouble on Busbars

If you only check a few areas, check these first:

- Around holes and slots.

- Especially punched holes. The exit side can carry a raised burr that affects seating or insulation washers.

- Edges near joint faces.

- Burrs near a contact area can stop a joint from sitting flat.

- Ends of bars.

- Saw cuts can leave sharp corners that snag sleeving and create handling risks.

- Corners on insulated bars

- Sharp corners increase the chance of tearing during installation.

Common Deburring and Edge Finishing Methods

There is no single best method. It depends on volume, geometry, material, and the finish required.

A) Manual deburring:- Good for prototypes and low-volume runs. It can include:

- hand deburring tools.

- files.

- abrasive pads.

It is flexible, but results can vary if it is not controlled and checked.

B) Machine edge finishing:- Often, the best route for consistency on repeat work:

- edge rounding machines.

- brushing machines.

- belt sanding for straight edges.

This is a strong option for copper and aluminium flat bars and busbars, where you want repeatable results.

C) Machined chamfers and radii:- If a busbar is CNC machined, you can specify chamfers or radii precisely. This is useful where:

- Tight clearances exist.

- Insulation requirements are strict.

- The edge finish is part of the assembly function.

D) Hole deburring and countersinking:- Holes often need special attention:

- removing the exit burr.

- lightly breaking the edge to avoid sharpness.

- ensuring washers and connectors sit properly.

For some designs, a controlled countersink is appropriate, but it should be intentional, not accidental.

E) What “good” looks like in simple terms:- A well-finished busbar should feel:

- smooth to the touch along edges.

- free of sharp corners.

- free of raised burrs around holes.

- consistent from part to part.

It should also stay practical. Overdoing edge rounding in the wrong place can reduce the contact area or change the fit of stacked laminates. The goal is reliability and assembly quality, not unnecessary material removal.

How to Specify Deburring on Your Drawings without Overcomplicating It

If you want consistent results, the biggest win is giving clear instructions. Here are a few simple approaches we see work well:

Option A: General deburr note

A common instruction is:

- Deburr all edges and holes.

- Remove all sharp edges.

This is better than nothing, but it can still be interpreted differently across suppliers.

Option B: Add a controlled edge break

If edge control matters, specify something like:

- Break sharp edges.

- Edge break X mm (where X is your preferred value).

- Radius edges were insulated.

Even a small, consistent edge break can dramatically reduce insulation issues.

Option C: Call out functional surfaces

If you have contact faces or joint areas that must remain flat and clean, call that out:

- Joint faces are to be kept free of scratches and raised burrs.

- No burrs around the hole seating areas.

That helps prevent well-intentioned finishing from affecting a critical surface.

If you are not sure how to write it, send your drawing and tell us how the busbar is being installed. We can suggest a sensible finishing note that suits the application.

- Quick checks you can do in your workshop or on-site.

- Run a glove lightly along the edges to feel for snags.

- Check the exit side of the holes for raised material.

- Look at corners that will be sleeved or coated.

- Confirm the joint faces seat flat before tightening.

- These checks take minutes and can prevent hours of rework.

A Helpful Next Step

If you are working on a new panel build, a repeat order, or a value-engineering exercise, we are happy to take a practical look before production starts. At ILF, we make and fabricate copper busbars in the UK and support projects with cutting, punching, bending, drilling, finishing, and plating, where it suits the application. We can also supply aluminium stock in the common forms when your project needs it.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.