In the modern manufacturing landscape, precision, sustainability, and efficiency are the cornerstones of successful production. When it comes to shaping copper into intricate or complex profiles, engineers and manufacturers are increasingly turning to extrusion instead of traditional machining. Both processes have their place, yet copper extrusion offers a series of technical, economic, and environmental advantages that make it ideal for contemporary engineering challenges.

This guide explores the key advantages of copper extrusion compared with machining, offering insight into why many industries are shifting their focus to more efficient forming methods.

Understanding Copper Extrusion

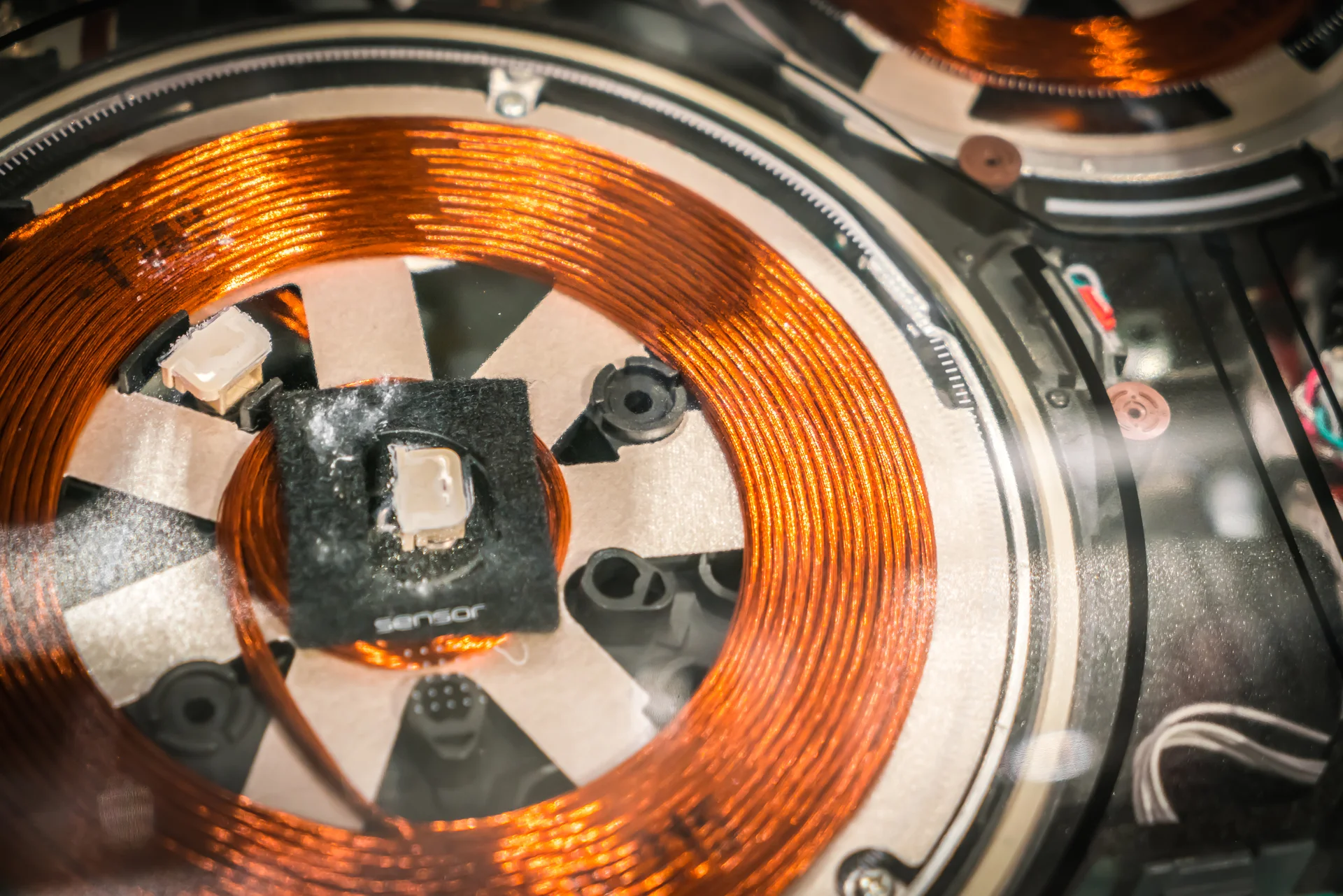

Copper extrusion is a forming method in which heated copper billets are driven through a specifically constructed die, resulting in a continuous length of material with a constant cross-section. This method may produce solid rods, tubes, and complicated bespoke profiles for use in electrical, construction, and industrial applications.

Unlike machining, which removes material from a solid block to achieve a desired shape, extrusion shapes the metal itself. This fundamental distinction has important implications for cost, waste reduction, and design flexibility.

Companies like ILF Products have experienced an increase in demand for extruded copper profiles due to their precision and versatility, notably in electrical and mechanical applications requiring high conductivity and robustness.

Why Choose Extrusion over Machining for Complex Profiles?

When comparing copper extrusion with traditional machining, several key advantages become clear, especially for projects involving intricate geometries or long production runs.

Material efficiency:

Machining removes large volumes of copper and generates substantial waste. Extrusion shapes the metal close to its final form, improving yield and cutting scrap. This saves money and supports sustainability goals by lowering waste and embodied carbon.

Design flexibility:

Extrusion enables complex profiles with internal cavities and consistent wall thickness in a single continuous step. Engineers can create optimised sections for heat exchangers, busbars, and connectors without compromising durability or conductivity.

Mechanical performance:

During extrusion, the grain structure aligns and refines, which boosts strength, toughness, and fatigue resistance. This makes extruded parts well-suited to demanding service where both electrical performance and mechanical integrity matter.

Cost and productivity:

While machining suits small batches or very tight local tolerances, it is time-intensive. Once a die is commissioned, extrusion produces long, repeatable lengths with minimal interruption, lowering unit cost on medium and large volumes. ILF Products often pairs extrusion with cutting, bending, or plating to meet precise specifications efficiently.

Consistency and repeatability:

Extrusion uses the same die and controlled conditions, delivering stable dimensions and surface quality from run to run. Machining can vary due to tool wear or setup differences.

Surface finish:

Extruded copper typically leaves the die with a smooth, uniform surface that needs little post-processing. This improves appearance and can enhance conductivity or sealing, reducing finishing time and total lead time.

Environmental and Sustainability Considerations

All manufacturing now prioritises sustainability, and copper extrusion fits this trend. Extrusion promotes green production by reducing energy and material waste.

Since copper is extremely recyclable, the extrusion technique makes it easier to incorporate recovered copper into production without compromising quality. This cyclical method promotes long-term resource conservation, which private and public projects appreciate more.

When Machining Still Has Its Place

Although extrusion has many advantages, machining is still a necessary technique in certain situations. It is great for making small batches of custom components, developing complex features that cannot be extruded, and obtaining extremely tight tolerances.

In many situations, producers utilise machining as a secondary operation following extrusion to refine dimensions or add specific design elements. Combining the two technologies gives you the best of both worlds: extrusion efficiency and machining precision.

Applications of Extruded Copper Profiles

Copper extrusion is widely used across sectors such as:

- Electrical engineering: Busbars, connectors, and terminals that require excellent conductivity.

- Construction: Architectural trims, rails, and frameworks with decorative appeal.

- Renewable energy: Components for solar systems and power distribution.

- HVAC systems: Tubes and channels for heat exchangers.

- Transport and rail: Conductive and structural components that balance strength and weight.

Each of these sectors benefits from the precision, consistency, and sustainability of extruded copper, reinforcing its growing role in modern engineering.

The Future of Copper Extrusion

Extrusion methods keep changing as technology does. Manufacturers can achieve ever-increasing precision while consuming less energy and waste thanks to automation, digital monitoring, and modern die design.

By fusing data-driven production with material science, copper extrusion will be able to address complicated design requirements economically and sustainably. Extrusion will undoubtedly continue to be a key component in the production of sophisticated copper components due to its demonstrated performance.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.