Aluminium busbars play an important role in modern power distribution. They offer a lightweight and cost-effective solution for electrical panels used in commercial, industrial and residential settings. Installing them correctly is essential for safety, performance and compliance with UK electrical standards. This guide explores the best practices for installing aluminium busbars, addressing preparation, installation, maintenance and safety.

Understanding the Role of Aluminium Busbars

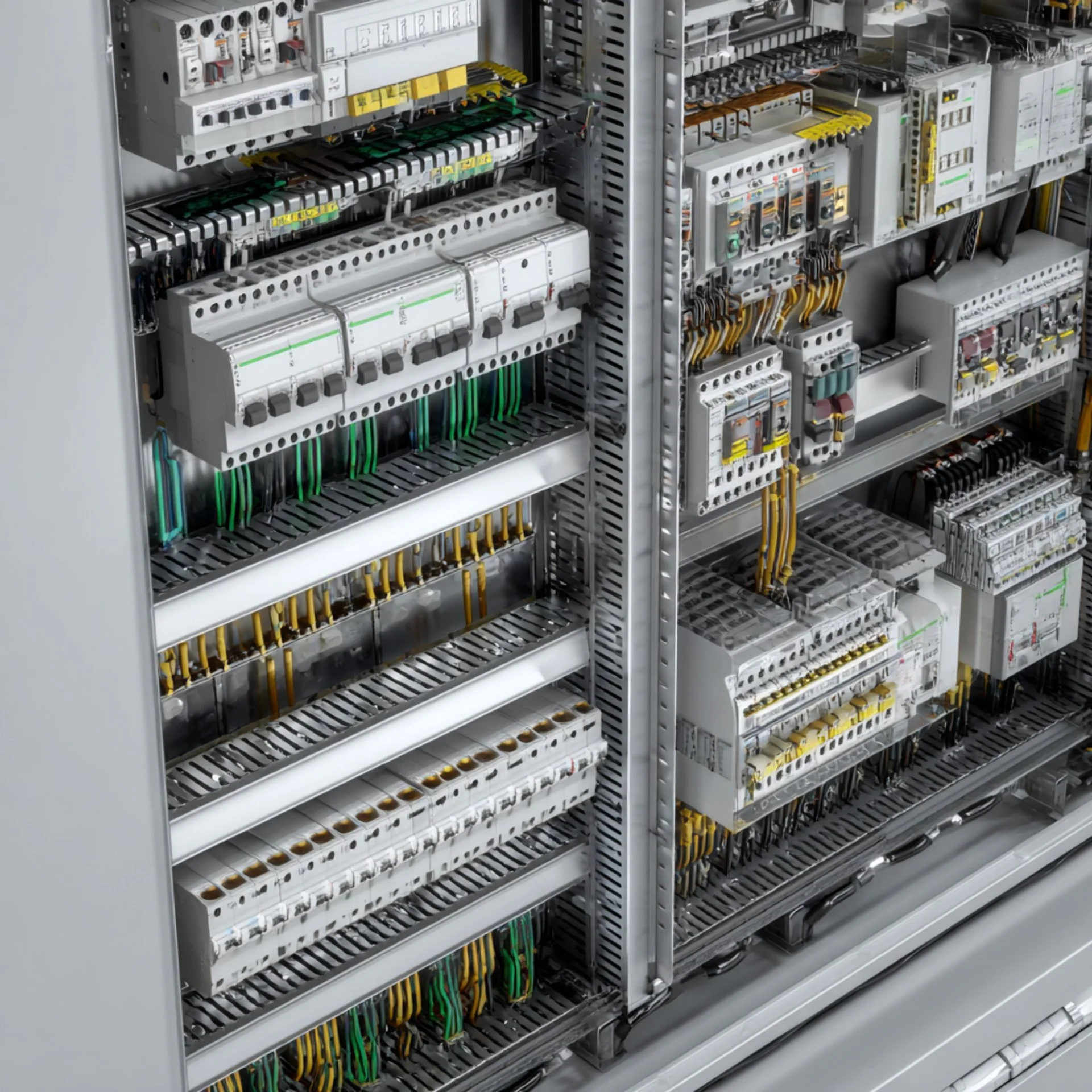

Busbars consist of long, solid strips or bars made of conductive material and carry large amounts of power quickly. Manufacturers widely use aluminium because it offers a low-cost, lightweight, and highly efficient solution for conducting electricity. You often find aluminium busbars in distribution boards, control screens, and switchgear.

Aluminium busbars help distribute current evenly and prevent heat from building up. It’s not enough to simply bolt them down; they need to be carefully planned, connected correctly, and inspected regularly to ensure they don’t fail or pose a risk.

Preparation Before Installing Aluminium Busbars

Successful installation starts with preparation. Choosing the right size, grade and surface treatment will determine how well the busbars perform under load.

Selecting the right grade and size

There are different grades of aluminium, and each one has a different amount of strength and conductivity. The grade should be right for the amount of power that the electrical system needs to handle. Busbars that are too small can get too hot, and bars that are too big can cost too much and take up too much space inside the panel.

The ampacity, or the amount of current that can be carried, should be found by using the panel’s design and the load that is predicted. Think about things like ventilation and temperature in the room because they have a direct effect on efficiency.

It’s also important to clean and treat the metal surface first. Aluminium can naturally oxidise, which makes it more resistant. When you clean properly, the contact resistance goes down and the conductivity is more stable.

Step-by-Step Installation Guidelines

Once preparation is complete, installation should follow structured steps that align with UK electrical standards and safety codes.

Ensuring secure connections

Connections are often the weakest point of any busbar system. Use approved fasteners, torque wrenches and proper jointing compounds to ensure low-resistance connections. Insufficient tightening can lead to arcing, while overtightening can damage the aluminium.

- Position the busbars correctly within the panel, ensuring clearance from other components.

- Apply a suitable conductive grease or joint compound to minimise oxidation.

- Use flat washers and spring washers where necessary to maintain secure pressure.

- Torque the bolts according to the manufacturer’s specifications.

- Label each busbar clearly to match the electrical diagram of the panel.

Certain panels also require insulation sleeves or barriers to prevent accidental contact and improve safety.

Common Mistakes to Avoid During Installation

Even experienced electricians can make errors when working with busbars. Some of the most frequent mistakes include:

- Incorrect sizing – Using the wrong cross-section for the intended current load can cause overheating.

- Improper jointing – Failure to use conductive paste or incorrect tightening of bolts increases resistance.

- Poor alignment – Misaligned busbars lead to stress on connections and eventual failure.

- Neglecting clearances – Inadequate spacing between busbars and other components raises the risk of short circuits.

Avoiding these mistakes helps ensure both efficiency and safety in the electrical panel.

Safety Considerations for Electrical Panel Work

Working with aluminium busbars requires strict adherence to electrical safety practices. All work should be carried out by qualified professionals in accordance with UK wiring regulations.

Important safety practices include:

- Always isolate the power supply before beginning installation.

- Wear appropriate PPE, including insulated gloves and protective eyewear.

- Follow lockout and tagout procedures to prevent accidental energisation.

- Keep tools in good condition and use insulated tools where required.

- Maintain proper ventilation when working in confined panel areas.

Companies such as ILF Products highlight the importance of following safe working methods when handling busbars and associated components. Prioritising safety not only protects workers but also ensures compliance with regulations.

Long-Term Maintenance and Inspection Tips

Installation is only part of the process. Aluminium busbars require ongoing maintenance to ensure they continue to perform reliably throughout their service life.

Monitoring performance over time

Frequent checks should be made for signs of corrosion, overheating, and links that aren’t tight. Thermal photography can find hotspots that you might not be able to see.

Care should be taken when cleaning so as not to damage the insulation or protection coatings. Having dust and other things inside electrical panels can make them work less well and raise the risk of a fire.

After being used for a while, fasteners may need to be tightened again because movements and changes in temperature can make them loosen. Keeping records of inspections helps maintain the system’s state and ensures that everyone is accountable.

Ensuring Reliable Electrical Panel Performance

Aluminium busbars are practical and popular in UK electrical panels. It takes preparation, secure connections, and maintenance to install them. Electricians can improve efficiency and avoid overheating, arcing, and failures by following best practices.

ILF Products and other UK industry suppliers support high-quality materials and installation techniques; however, installers must ensure that every panel fulfils safety and performance criteria.

Understanding these best practices helps you produce reliable, long-lasting outcomes when building or upgrading a panel.

Milly Edwards

Sales and Marketing Executive: Responsible for creating content for ILF's social media channels, website, print media and promotional work.