TECHNOLOGY

GET A METAL BENDING QUOTE TODAY!

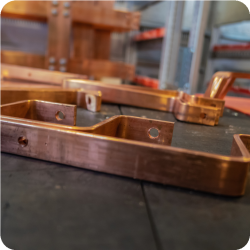

Metal bending services at ILF Ltd are designed to meet the highest standards of precision and efficiency. Using the latest CNC-controlled and fully automated machinery, we deliver expertly crafted bends across a wide range of materials, including copper busbars, aluminium sheets, and steel components.

Our facility is equipped with advanced bending solutions such as EHRT bending machines and Vaski punching systems, ensuring each project benefits from outstanding accuracy and repeatability. These cutting-edge technologies allow us to handle complex fabrication requirements while reducing lead times and maintaining exceptional consistency.

Whether you’re working on large-scale electrical infrastructure or bespoke metalwork, we provide a reliable, high-quality solution backed by industry expertise and a commitment to excellence in precision metal bending.

Metal bending is the process of deforming metal to create specific angles and shapes, commonly in ‘V’ or ‘U’ forms. This is typically achieved using a press brake or dedicated bending machines. While the concept may seem simple, maintaining accuracy and consistency throughout is a specialist task. There are several types of bending machines, including mechanical, hydraulic, pneumatic, and CNC press brakes, each designed to apply force in a controlled manner depending on the material and the design.

We are happy to use modern EHRT bending equipment, which is world-renowned for its precision. These machines can bend copper and aluminium bars with a tolerance of +/- 0.1°, ensuring flawless repeatability throughout all production runs.

Advantages of the EHRT Bending Machine:

We can use EHRT technology to create custom metal components for industries such as electrical switchgear, renewable energy, automotive, and more, guaranteeing that your designs are realised with dependability and precision.

As a leading stockholder, we also utilise advanced Vaski punching machines, which are widely recognised for their high precision and operational efficiency in metal punching and bending. Built for reliability and consistency, these machines are ideal for demanding industrial applications that require accurate and repeatable results.

Vaski punching machines support a wide range of materials, including steel, aluminium, and copper, and are capable of executing complex punching and bending operations with ease. Their automation capabilities enhance productivity, minimise material waste, and reduce manual labour. Read the full breakdown of Vaski punching machine capabilities in our blog.

At ILF, we’re more than a metal fabrication service; we’re your engineering partner. Our Midlands-based facility gives us a strategic location to serve clients across the UK with short lead times and high responsiveness. Whether you’re producing a single prototype or require batch production, our team is committed to quality, flexibility, and expert communication throughout the process.

Supporting Industries Across the UK

We support a broad range of sectors, including:

From initial drawings to final delivery, we ensure each product meets your exact technical requirements. All our processes are quality-controlled and backed by years of experience in custom metal bending.

An invaluable link in your supply chain delivering quality products on time, every time

FOR MORE INFORMATION TELEPHONE OUR SALES TEAM ON 01543 226816

Ready to discuss your metal bending requirements with us? Speak with our expert team to find the right solution for your next project. Call us today on 01543 226816 or email sales@ilfproducts.co.uk.

We look forward to helping you bring your designs to life efficiently, accurately, and on time.

Offering quality and precision as standard in busbar and metal component supply